This Clothing and Protection Brand Makes Its Foray into MTB Components

Leatt has recently entered the components market with some impressive-looking pedals, handlebars, stems, and grips.

What happens when a clothing brand makes bike parts?

Photo: LeattIn a surprising announcement, Leatt has made its exciting foray into the mountain bike components market with some impressive-looking pedals, handlebars, stems, and grips. While this wasn’t on my 2025 bingo card, it’s not entirely surprising, as Leatt has never been a stranger to continued expansion in the industry. If we follow the trends, these components are likely more than just another option that consumers are inundated with. Although not everything in this launch is immediately available, the statement has been made, and I’ll be excited to give these components a thorough review over the summer.

Table of Contents

A little backstory was provided in the press release that came through my inbox, which shares that Leatt’s founder, Dr. Chris Leatt, an XC enthusiast, collaborated with product managers to design lightweight yet durable MTB components using some innovative materials. Exploring the properties of magnesium alloy, which is commonly found in fork lowers and aircraft parts, they aimed for a magnesium stem but later expanded to include pedals as well as aluminum versions of the magnesium counterparts.

The development took longer than expected due to the complexities of magnesium manufacturing, doubling the timeline to four years. However, Leatt is finally pulling back the curtain on its CeraMAG components: pedals and stems made from a CERAmic-coated MAGnesium alloy, known for its lightweight, high strength, and 100% recyclability, combined with a ceramic coating for enhanced wear and corrosion resistance.

Shop the new Leatt components at Leatt.com

As previously stated, not everything is ready for consumers right now, but all the aluminum components are currently available. The CeraMAG pedals will be available within a month, and the CeraMAG stems are expected to be available in July, pending a smooth production process.

Flat Pedals

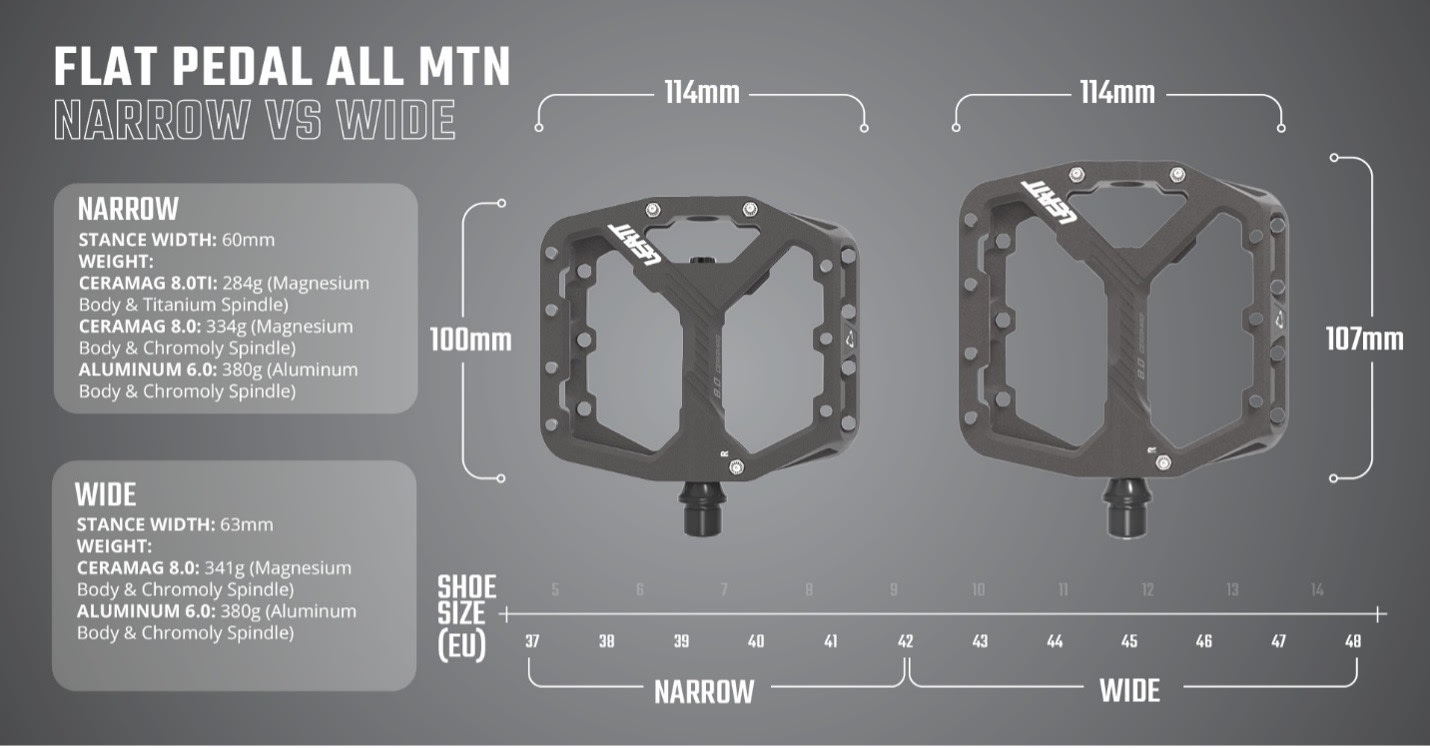

The flat pedals start at 284g per pair in the CeraMAG version with (Grade 5) titanium axles and 338g with a chromoly steel axle. The aluminum versions (available in silver, black, and bronze) weigh 381g with steel axles. Although the material might differ, they share a few things in common.

- 5-axis CNC-machined body

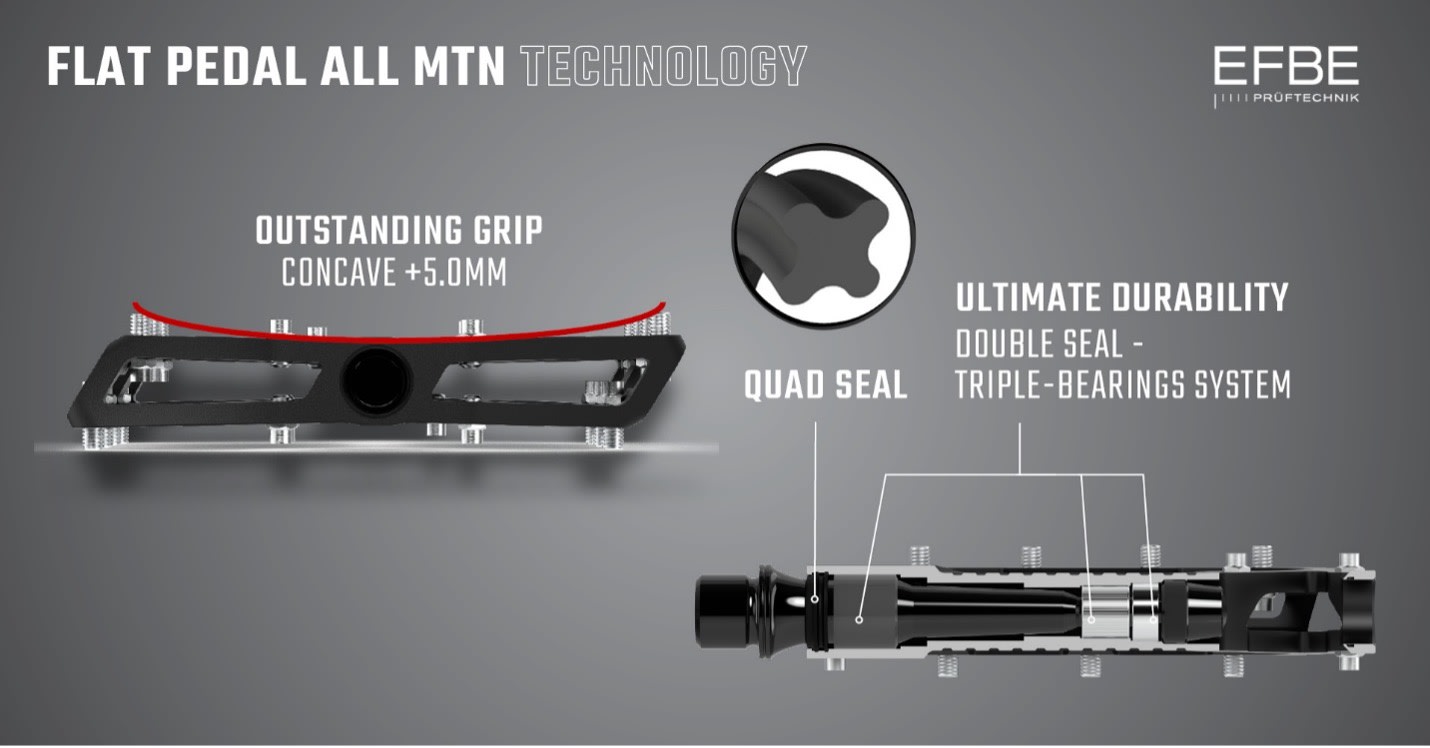

- Fully serviceable triple-bearings system (LSL self-lubricating bushing, a needle

- bearing, and a sealed ball bearing)

- Quad lip seals ensure the internals remain dirt-free even in the harshest conditions

- 16mm thickness with a 5mm concavity for a good grip and pedal feel

- 10 stainless steel pins per side (7 bottom loaded threaded pins and 3 top loaded

- diamond studs)

- Two platform sizes available: 114mm (length) x 2 widths: narrow (100mm) and wide

- (107mm)

- Tested and certified to EFBE EPAC Gravity TRI-TEST® standard (category 5).

- Please note: only the top-of-the-line CeraMAG Ti pedals is A) only available in the

- narrow version, and B) only certified to EFBE EPAC category 4 (titanium is simply a

- touch softer than chromoly).

- Titanium axle upgrade kits and full bearing replacement kits are available.

Clipless Pedals

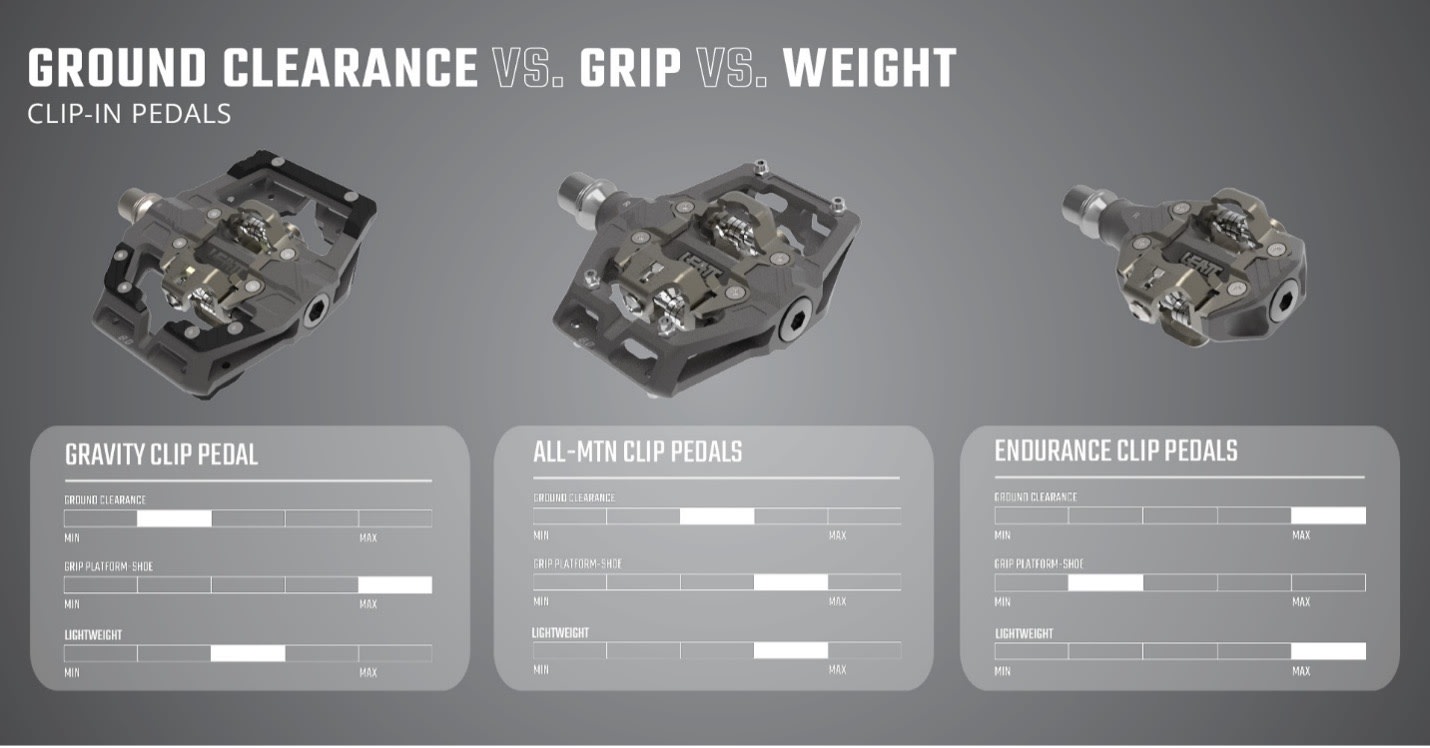

The same axle and bearing system is also used in Leatt’s clipless pedals, which are available in three models: the Endurance pedal with no platform or cage around the binding interface. The AllMtn utilizes a small platform to protect the binding, whereas the Gravity features a large platform for exceptional durability.

Each pedal is offered in CeraMAG versions, but only the Endurance pedal is available with titanium axles, because…performance. All three pedals use the familiar and reliable SPD-compatible clipless system (cleats included with pedals). Weights range from 298 grams per pair for the Endurance CeraMAG Ti, to 520 grams for the aluminum Gravity pedals.

Available colors include CeraGrey, as well as silver, black, and bronze for all aluminum versions.

- Aluminum flat Pedals: MSRPUSD/EUR 169 / CAD 229 / GBP 149

- CeraMAG Ti flat pedals MSRP: USD/EUR 319 / CAD 439 / GBP 279

- Aluminum Endurance Clip-In Pedals MSRP: USD/EUR 159 / CAD 219 / GBP 139

- CeraMAG Ti Endurance Clip-In Pedals MSRP: USD/EUR 339 / CAD 459 / GBP 299

- Aluminum All Mountain Clip-In Pedals MSRP: USD/EUR 189 / CAD 259 / GBP 165

- CeraMAG All Mountain Clip-In Pedals MSRP: USD/EUR 259 / CAD 355 / GBP 229

- Aluminum Gravity Clip-In Pedals MSRP: USD/EUR 199 / CAD 269 / GBP 175

- CeraMAG Clip-In Pedals MSRP: USD/EUR 269 / CAD 365 / GBP 239

Stems

The CeraMAG Ti stem comes with titanium bolts to reduce weight, coming in at 100g for 33mm length, 103g for 40mm, and 111g for 50mm. Stems are also available with stainless steel bolts in both CeraMAG and aluminum versions, the latter weighing from 141g.

- Aluminum MSRP: USD/EUR 129 / CAD 175 / GBP 109

- CeraMAG Ti in 33mm MSRP: USD/EUR 239 / CAD 325 / GBP 209

The stems all share the following similarities.

- Intensive, 5-axis CNC-machining minimizes weight and defines the distinctive Leatt

- aesthetic

- Zero-gap faceplate and 210 ̊ handlebar wrap to evenly spread the clamping force,

- reducing the risk of damaging handlebars

- Interlocking faceplate interface increases strength and makes installation easy

- Extra-wide (65 mm) clamping platform for maximum control and steering precision

- Round head bolts help protect knees

- Steerer tube seal cap prevents dirt and debris from entering the steer tube

- Tested and certified to EFBE EPAC Gravity TRI-TEST® standard (category 5).

- 35mm bar diameter, only.

Grips

Leatt’s Reaflex 6.0 Grips feature a unique Reaflex gel-infused core, a material commonly used in Leatt’s pads. This core effectively combats arm pump thanks to its outstanding vibration-damping properties. With non-Newtonian characteristics, Reaflex adjusts its damping abilities in response to the forces applied, making it particularly effective at reducing micro-vibrations.

This Small Component Could Add Big Comfort To Your Mountain Bike Rides

A gel-infused mountain bike grip could reduce arm fatigue and improve control.

Currently, there is one profile available in two diameters: regular at 33/31mm and thin at 31/29mm, along with four color options. These grips use a tapered profile that has more material on the outer edge, increasing contact and further alleviating hand pressure while enhancing damping. Soft, flexible ribs in the thumb and forefinger areas help prevent slippage, and the half-waffle and triangular tread block patterns provide excellent traction for the phalanges.

Handlebars

While the bars may not be extraordinary, they feature an appealing design consisting of both shot-peened and polished sections, in silver and black, with tonal graphics. Impressively, these bars are only 284 grams at the full 800mm width, which is pretty good for a 7050 aluminum bar. They boast a traditional 9° backsweep and come in two rise options (38mm / 23mm) with a 35mm clamping standard. Sorry, 31.8 fans.

Additionally, they always include custom ReaFlex 6.0 Grips (black/regular width) in the package, and that will only run you 119.99 USD/EUR, 159.99 CAD, and 105 GBP, which is a pretty tempting value. If you prefer stiff bars for optimal steering control, paired with dampening grips that help minimize micro-vibrations and arm pump, these could be ideal for you. They also feature a generous clamping area (100mm), which accommodates even the widest direct mount stems. Furthermore, Leatt plans to release its own fully CNC’d aluminum direct mount stem later this July.